Dredging

Dredging improves the efficiency of deep draft commercial navigation and reduces contaminated sediment from washing into Lake Michigan.

Each year more than 100,000 cubic yards (CY) of contaminated sediment washes into the lake, including approximately 67,000 pounds of chromium, 100,000 pounds of lead, and 420 pounds of polychlorinated biphenyls (PCBs).

The Indiana Harbor and Canal (IHC) was not dredged from 1972 to 2012 due to a lack of suitable storage area for the contaminated sediments. The Confined Disposal Facility (CDF) was constructed to provide storage for the sediments. Dredging began in 2012 after the completion of the CDF to remove sediment that accumulated between 1972 and 2012, designated the “backlog sediment”. The completed backlog dredging produced approximately 1.7 million CY of dredged materials.

July 2021 – June 2024, USACE conducted the Phase 2 dike project to expand the CDF exterior dikes by 11 feet to maintain sufficient storage capacity for the intended project life, consistent with the original project authorization and plan. After the dike raise, maintenance dredging resumed as required to remove re-accumulated sediments and maintain navigable depths in the harbor and canal.

What is Dredging?

Dredging is performed using a closed bucket (or clamshell bucket) mechanical dredge. The bucket scoops up sediment from the bottom of the waterway and loads it onto a barge for transport to the CDF.

The CDF operates as a "ponded" facility, which means the sediment is mixed with water to reduce the risk of potential air emissions. As the dredged material is unloaded from the barge, it is mixed with water from the CDF to make a mud mixture called a “slurry”. This slurry is then pumped into the CDF cells in a process called hydraulic off-loading. As the sediment settles to the bottom, the water that remains at the surface is then recycled and used for additional sediment placement. Air monitoring is conducted to ensure the safety of staff and the community.

Various dredging and placement alternatives were considered in an economic and environmental analysis performed by the USACE Engineer Research and Development Center. This approach was the least costly of those considered and has minimal environmental impacts.

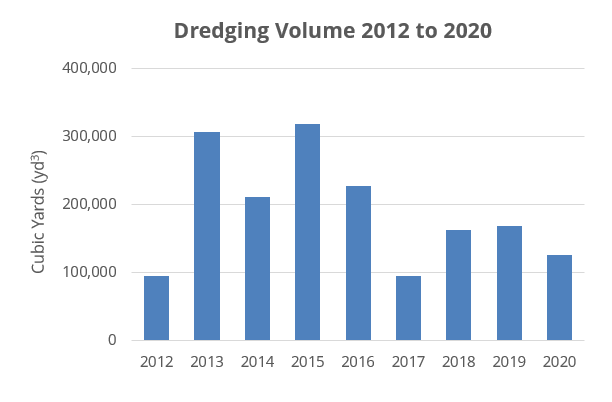

Dredging Volume

The chart below shows a summary of dredging volume to present. Dredging did not take place from July 2021 to September 2024 due to dike expansion construction.

| Year | Volume (Cubic Yards) |

|---|---|

| 2012 | 93,937 |

| 2013 | 305,947 |

| 2014 | 210,099 |

| 2015 | 318,202 |

| 2016 | 226,821 |

| 2017 | 94,054 |

| 2018 | 162,592 |

| 2019 | 167,845 |

| 2020 | 125,689 |

| 2024 | 84,046 |

Map showing dredging amounts (2012-2020)

Map showing dredging amounts (2012-2020) Map showing dredging amounts (2024)

Map showing dredging amounts (2024)

Dredging Schedule

During dredging, the typical work schedule is 24 hours a day, six or seven days a week. Each day consists of two 12-hour shifts.

- Working at night reduces the effects of bridge openings on local traffic

- Approximately half of all bridge openings will occur at night

- Keeping the dredge barge constantly staffed prevents the need to move on- and off-station each day

- This increases the work-time versus move-time ratio, increasing the productivity of each crew

See Traffic and Bridge Operations for details on detours and operations.

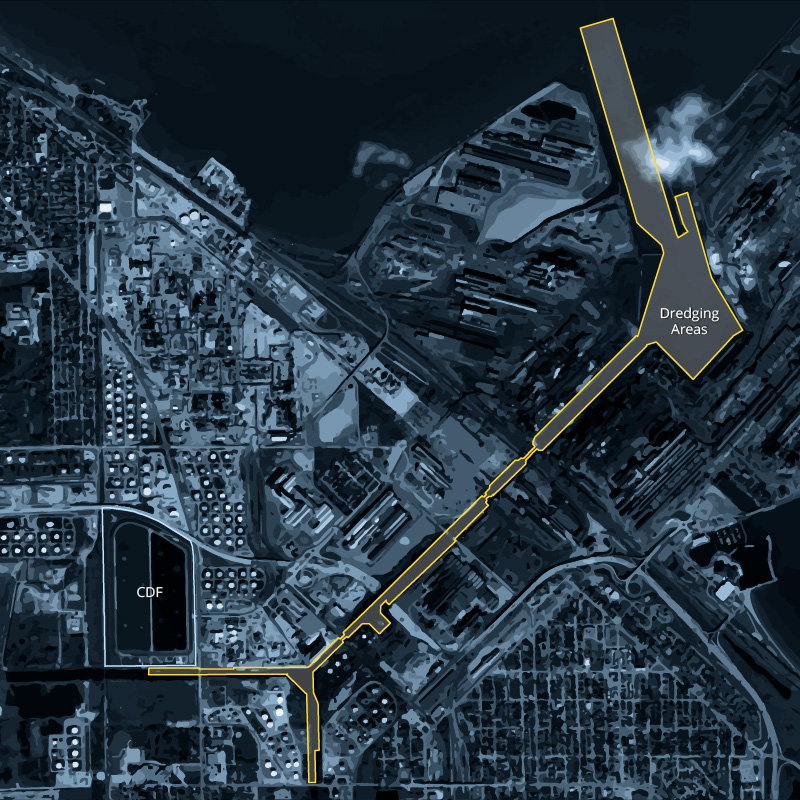

Dredging Areas

The map below shows the dredging areas in the Indiana Harbor and Canal, as well as the location of the CDF.

Notice to Mariners

Dredging operations are likely to occur throughout the Indiana Harbor and associated canals. The dredge will consist of a crane on the Derrick 73 spud barge, which will be located in or near the dredging areas. The tug David R Schanock will push barges between the dredge and the Confined Disposal Facility (CDF).

Access to navigation in all areas will be available upon advance request. Vessels will need to coordinate passages with the tug David R Schanock, particularly in restricted channel widths, such as at bridges and at the BP North America dock construction site. Standard U.S. Coast Guard rules of the road and signals will be used for safe vessel passages.

Mariners are requested to contact the dredge Derrick 73 spud barge and the tug David R Schanock at least one hour in advance to coordinate details of passage, particularly if the dredge would need to relocate. The dredge or tug can be contacted on marine radio channel 16 or 18 during dredging operation working time periods.